Clear Instructions:

Confusing & Inconsistent->Uniform & Coherent

Tolomatic is a Minnesota-based custom manufacturer of actuators. I was brought on to the marketing team through RobertHalf’s Creative Division to update and apply corrections to a set of 51 parts sheets. Over the three months I was employed, the project evolved to encompass the improvement of elements as well as the application of those elements consistently across all the parts sheets.

Technical Writing

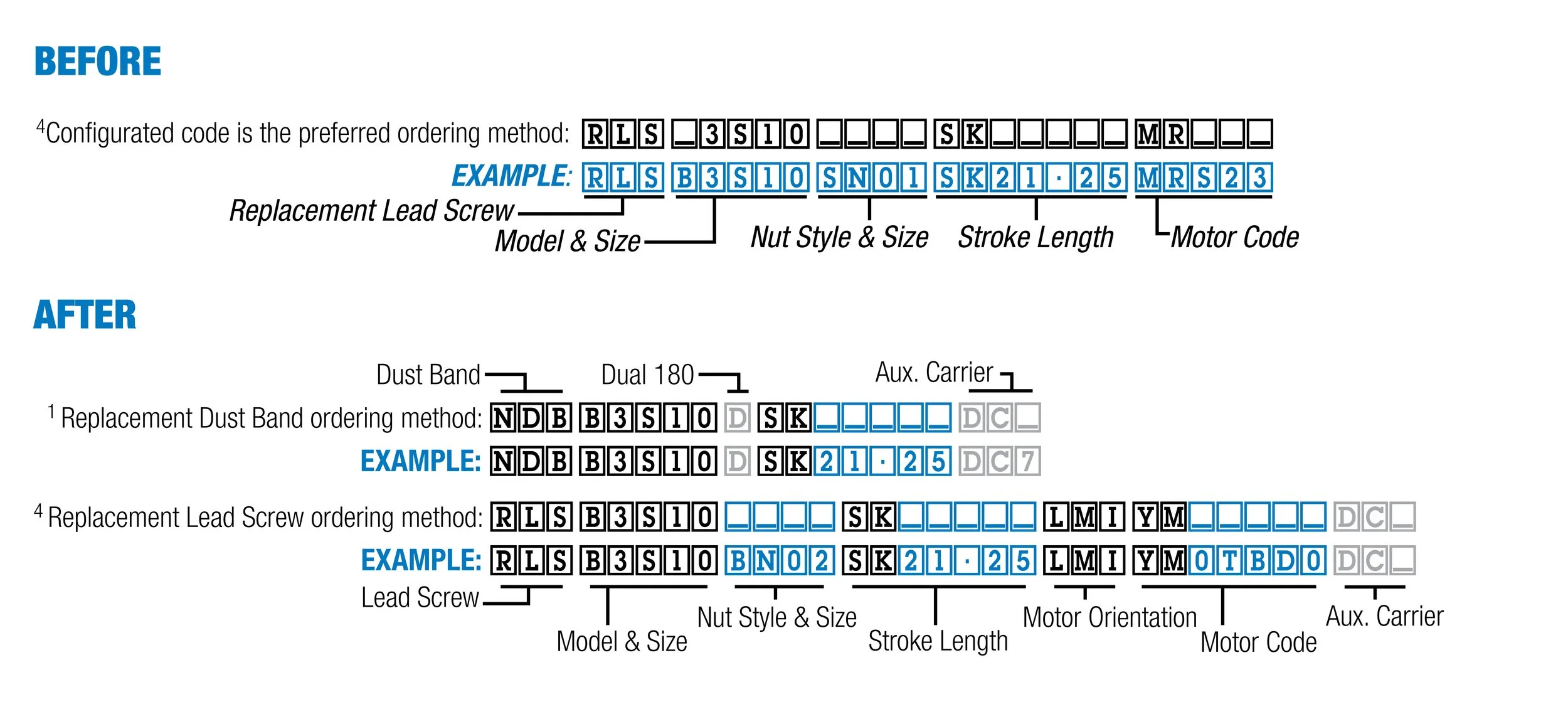

Upon starting my edits, I noticed that different subsets of the 51 parts sheets had different ways of giving parts ordering instructions. The ordering instructions were also confusing and I had difficulty making the corrections requested of me.

I asked my teammates a multitude of questions regarding the process, procedure, and definitions of the parts of the configuration code used to place an order. Through this questioning and trying to understand the instructions, my co-worker and I ideated and refined a solution that built upon one of the instruction methods already in use.

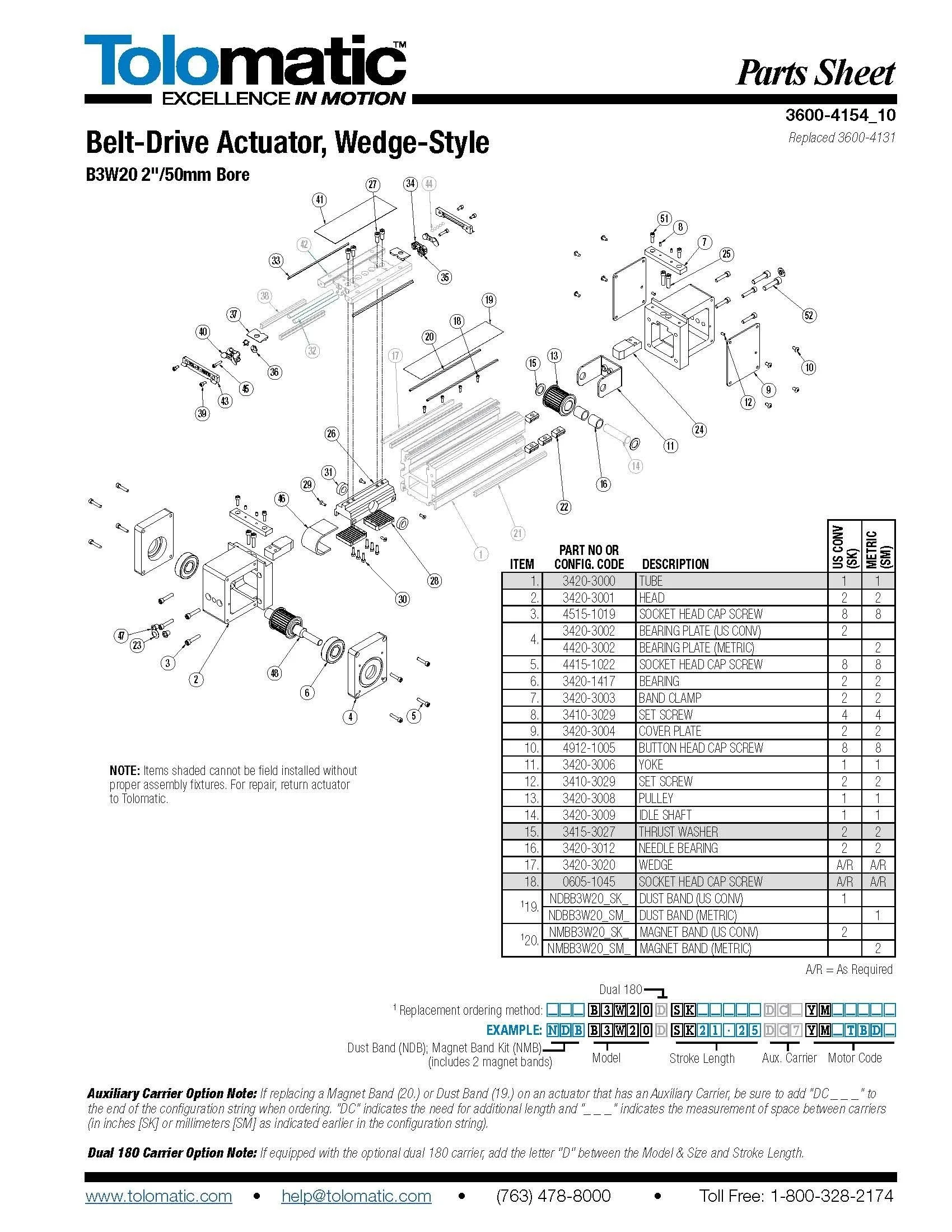

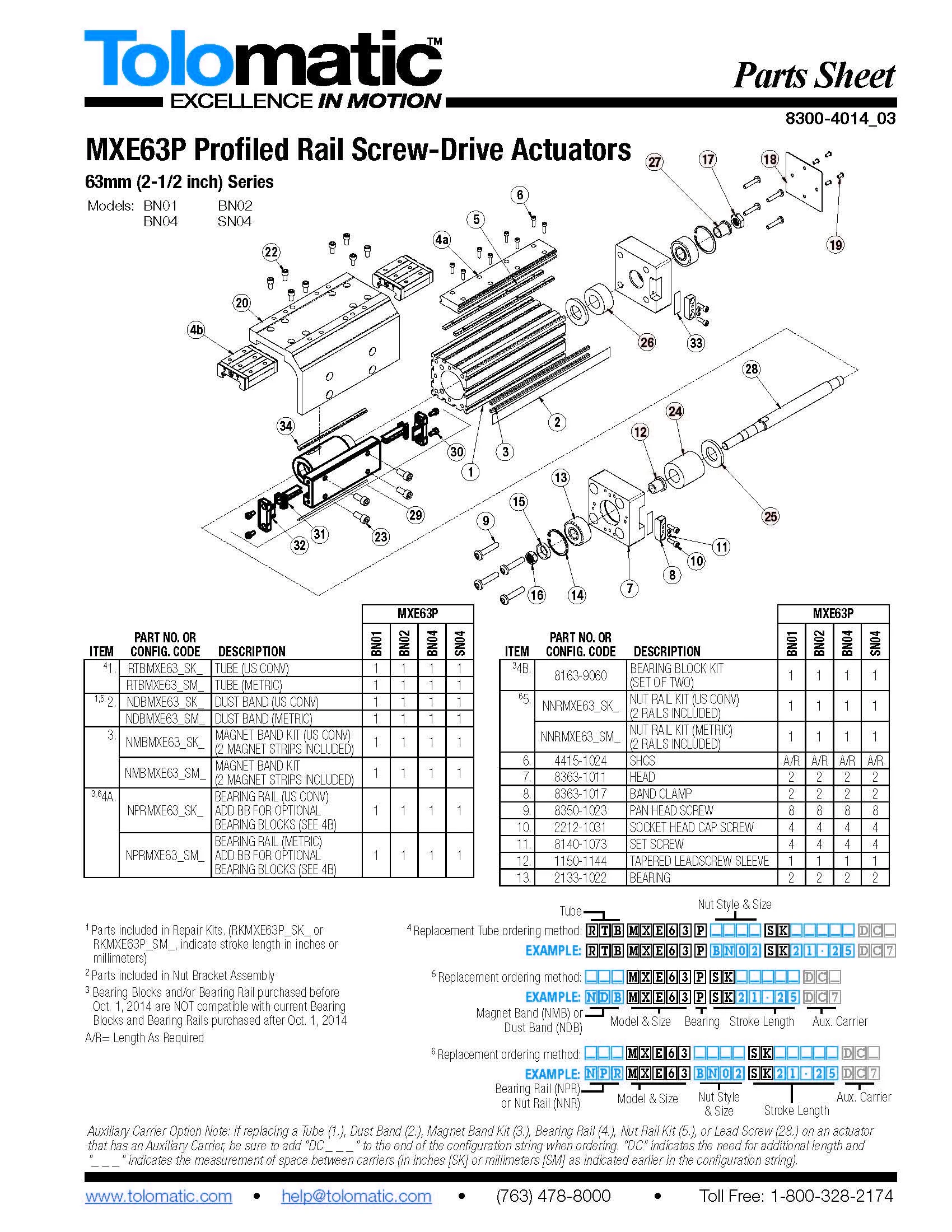

The solution we devised clarified the difference in the configuration strands by including specific examples adjacent to the part and using color variations to delineate sections of the ordering code. This configuration code example system was applied across all 51 parts sheets in the original project as well as an additional 11 parts sheets.

Adobe InDesign Expertise

During my three-month contract, I was assigned to convert, update, edit, and clean 51 parts sheets using Adobe InDesign. Many of the files were first-generation conversions from QuarkXpress or PageMaker. I worked tirelessly to clean up each file after the conversion using Libraries to streamline the application of paragraph and character styles as well as update common images. I worked with tables, text block formatting, and parent pages. I applied best practices to each file so that the next designer who worked with them could easily do so.

I also edited the technical illustrations in Adobe Illustrator as part of this contract. These edits included tracing and applying new parts, deleting parts, and renumbering and adjusting labels.

Project Management and Tracking

After realizing that my team didn’t have a formal way of tracking projects, I devised an excel file containing checklists as well as equations tallying the number of sheets that were at what stage and in what department’s hands. This helped our team advance the parts sheet project smoothly and for the department head to be aware of its progress.